Extruded Products

Contact Us

At Cable Core, we are dedicated to providing comprehensive manufacturing solutions tailored to a wide range of industries. Our expertise in custom-engineered components, including precision extrusion tools, ensures that you have the right products to optimize your manufacturing processes. Here at Cable Core, we can custom manufacture most projects. If you have a custom job, fill out our contact form or give us a call today! With a focus on innovation and quality, we cater to the unique needs of various applications, making us a trusted partner in the manufacturing sector.

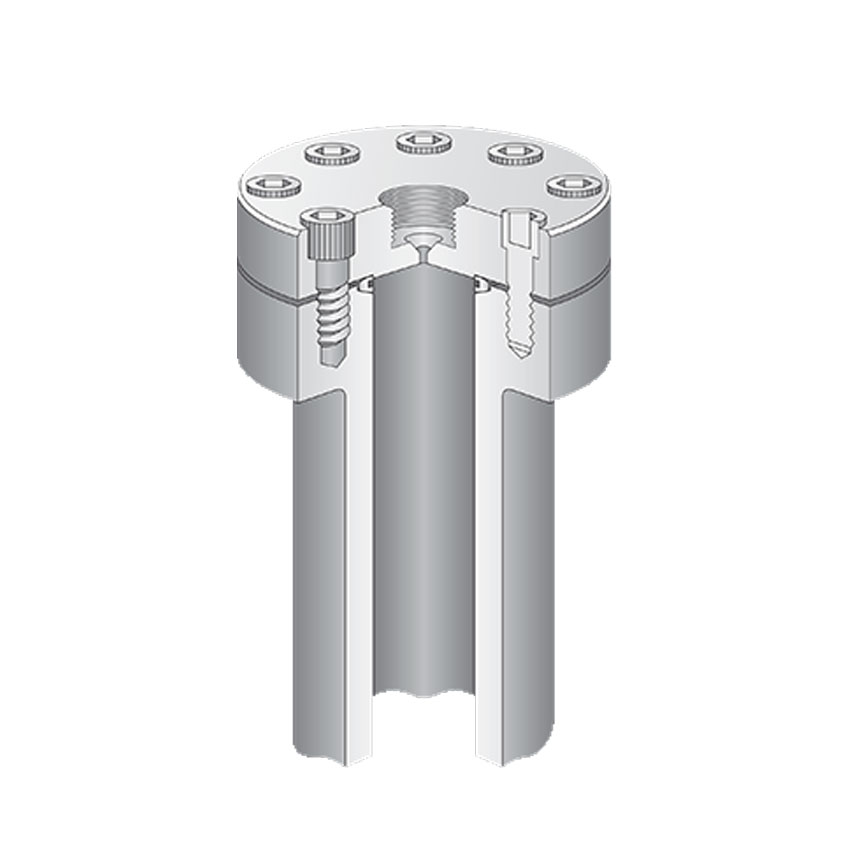

Extrusion Crossheads and In-Line Heads

Single Layer, Dual Layer, Multi Layer (up to 5 layers)

Cable Core Engineering manufactures & designs fixed center cross heads from (0.40mm to 120 mm diameter) with single layer, multi-layer stripe (pattern) for several kind of compounds. Using advanced alloy steel, we manufacture crossheads designed for a wide variety of polymers like PVC, HDPE, PP, and nylon, ensuring reliable performance across industries such as telecommunications, automotive, and medical. Each unit is tailored to fit extrusion lines perfectly, reducing production deviations and increasing efficiency. We provide crossheads for specialized applications, including optical fibers, submersible cables, and high-tension power lines, engineered to improve overall production throughput.

Extrusion Tips and Dies

We manufacture tips and dies with industry-leading precision, offering custom solutions for a variety of extrusion needs. Our high-grade steel ensures durability and consistency across applications such as multi-lumen tubing, wire and cable insulation, hose extrusion, and blown film production. The tailored designs offer specialized features, such as fixed-center tips and multi-lumen configurations, optimized for complex extrusions. Each tool is developed through rigorous testing, ensuring alignment with your exact extrusion requirements. These versatile tools are crucial for manufacturers looking to improve extrusion quality and reduce downtime. Choose between Custom Tips, Fixed Center Shoulder Tips, Profile Tips, Tapered Style Tips, Threaded Style Tips, Single & Multi-Lumen Tips, Face Seal Dies, Floating Dies, or Shoulder Dies.

Learn More About Extrusion Tips Learn More About Extrusion Dies

Extrusion Screws

Single Flighted Screws, Multi-Flighted Screws, Variable Lead Screws, Barrier Screws, Multi Section Screws, or Single/Multiple Mixer Selection Screws

Our extensive range of extrusion screws, including single-flight, multi-flight, and barrier screws, are designed for maximum material flow efficiency. We offer screws for a range of applications such as PVC pipe extrusion, injection molding, and cable coating, with customizable diameters and lengths tailored to your specific system. Using cutting-edge technology and rigorous quality control, each screw undergoes hardness testing to ensure maximum durability and performance. Multi-section and mixer screws allow for advanced material blending, perfect for industries requiring consistent, high-quality output with minimal maintenance.

The product portfolio that we offer includes a broad array of screw types and designs ranging in diameter from 40 mm to 150 mm and up to 4500 mm in length with hardness (Rockwell – HRC) as per the requirement of the client.

Accessories

We can provide accessories like Breaker Plates, Wedge Rings, Clamps, Flages etc.

Breaker Plates

Wedge Rings (Anti-Extrusion Rings)

Wedge rings, or anti-extrusion rings, are essential for maintaining the integrity of o-rings in high-pressure environments. Typically made from hard, extrusion-resistant materials like high-durometer Nitrile or PTFE, our custom wedge rings are designed to prevent o-ring extrusion, ensuring a proper seal under extreme conditions. These rings are vital for systems requiring precise sealing, particularly in high-stress extrusion applications. Cable Core’s wedge rings are engineered to fit perfectly within your extrusion system, enhancing durability and preventing costly downtime.

Clamps

Flanges

Why Core Engineering Company?

As a versatile manufacturing leader, Cable Core is committed to delivering high-quality components that enhance production efficiency and reliability. Our tailored solutions are designed to meet the evolving demands of your industry. Get in touch with us today to discover how our engineering capabilities can elevate your manufacturing processes!