High Quality Custom Extrusion Die Manufacturers

Contact Us

Whether you need a custom die for your plastic, rubber, or metal extrusion processes, our experienced team can design and manufacture a die that meets your exact specifications. Our state-of-the-art facilities and advanced technology allow us to produce extrusion dies with tight tolerances, ensuring consistent and accurate results every time. Contact us to learn more or arrange a consultation!

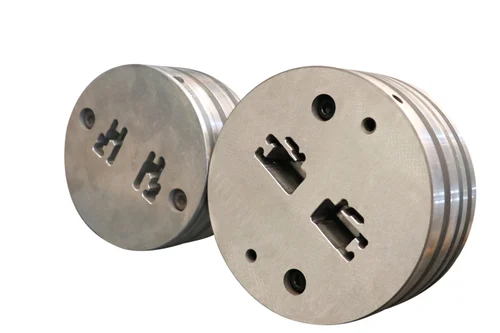

Basics on Extrusion Dies

When we talk about extrusion, we are referring to the process of shaping a material into a specific cross-sectional profile by forcing it through a die. Extrusion dies play a critical role in this process as they determine the shape and dimensions of the final product.

Extrusion dies are typically made from high-quality tool steels or carbides, which can withstand high temperatures and pressures. They are designed with precision in mind, with intricate features such as cooling channels, land widths, and die angles that all contribute to the final product’s quality.

Precision Manufacturing

Our manufacturing process involves using state-of-the-art CNC machines and EDM (electrical discharge machining) technology to produce extrusion dies with unparalleled accuracy and precision. Our team of highly skilled extrusion die manufacturers carefully monitor each step of the manufacturing process to ensure that every detail is executed flawlessly.

We also utilize advanced surface treatments and coatings to further enhance the durability and performance of our custom extrusion dies. These treatments can improve resistance to wear, corrosion, and heat, prolonging the lifespan of the die and ensuring consistent quality in your production processes.

Quality Control

At Core Engineering Company, we understand that the production of extrusion dies requires a high level of quality control. That’s why we have strict quality control measures in place at every stage of the design and manufacturing process. This includes thorough inspections and testing to ensure that our custom extrusion dies meet all required specifications before they are delivered to our clients.

Over 40 Years of Quality Services

For over 40 years, Core Engineering Company has been providing high-precision extrusion products and services to clients in various industries. Our commitment to quality, innovation, and customer satisfaction has made us a trusted name among extrusion die manufacturers.

So if you’re in need of a custom extrusion die for your specific application, trust the experts at Core Engineering Company. Contact us today to learn more about our services and how we can help you achieve superior results in your extrusion processes. We look forward to working with you!